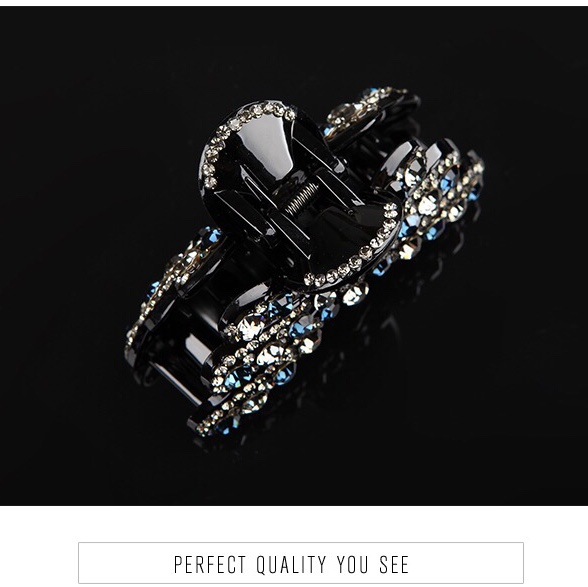

1335 Point Drill Claw – Where Industrial Power Meets Colorful Identity

In the world of heavy-duty machinery and relentless industrial operations, tools are often judged solely by their performance — strength, endurance, precision. Yet, what if a tool could do more than just deliver results? What if it could also speak — through color, identity, and purpose? The 1335 Point Drill Claw isn’t just another component in your drilling system; it’s a statement of innovation, engineered for power and designed for distinction.

When Industrial Strength Meets Visual Expression

For decades, factory floors and construction sites have been dominated by monochrome metal — greys, blacks, and the occasional rust stain. Tools blend into the background, indistinguishable from one another. But in high-stakes environments where efficiency and safety are paramount, visibility matters. The 1335 Point Drill Claw challenges this tradition by introducing a spectrum of color options that transform utility into identity.

Available in multiple vibrant finishes — from deep crimson to electric blue and safety yellow — these drill claws bring a new level of visual clarity to industrial settings. More than just aesthetic flair, the colors serve as an immediate cue, turning a simple attachment into a communicative element across teams and tasks.

Engineered for Extremes: The Science Behind the Strength

Beneath the colorful surface lies a core of uncompromising engineering. Crafted from high-grade alloy steel, the 1335 Point Drill Claw undergoes a proprietary heat treatment process that enhances hardness while maintaining structural resilience. This balance ensures the claw can withstand repeated impact, abrasion, and thermal stress without fracturing or deforming.

The geometric design of the drill point optimizes penetration force, reducing operational resistance and minimizing wear over time. Whether boring through dense rock formations or cutting into reinforced concrete, the claw maintains consistent performance across thousands of cycles. Its large-profile structure further distributes load evenly, preventing premature failure at stress points — a common issue in lesser-grade alternatives.

Color as a Workflow Tool: Beyond Aesthetics

In complex worksites, confusion costs time and risks safety. The 1335 Point Drill Claw leverages color not as decoration, but as a smart management tool. Imagine assigning red claws to demolition crews, green to maintenance units, and blue to installation teams. With a single glance, supervisors can verify correct tool deployment, reducing cross-use errors and streamlining accountability.

This color-coding system extends to task-specific configurations — different drilling depths, angles, or material compatibilities can be instantly recognized. In fast-paced environments like steel fabrication plants or tunneling projects, such visual cues dramatically improve coordination and reduce downtime caused by miscommunication.

Real-World Resilience: Tested in the Toughest Conditions

The true test of any industrial tool isn't in the lab — it's in the field. The 1335 Point Drill Claw has been deployed across some of the most demanding environments: from humid, salt-laden tunnels beneath coastal cities to scorching desert quarries where surface temperatures exceed 50°C. In each scenario, the claw maintains its integrity, with minimal wear even after weeks of non-stop operation.

Its corrosion-resistant coating ensures longevity in wet or chemically aggressive atmospheres, while the reinforced tip geometry resists chipping when encountering embedded rebar or fractured strata. Feedback from site engineers consistently highlights reduced replacement frequency and lower total cost of ownership compared to standard models.

Custom Identity, Built to Order

For enterprises seeking deeper integration, we offer dedicated color customization. Need a drill claw in your company’s brand tones? Want to align with project-specific ISO coding standards? Our flexible manufacturing line supports special color requests upon consultation with customer service. This capability reflects a broader shift in B2B tooling — from mass production to tailored solutions that reflect operational needs and corporate identity.

Designed as a System, Not a Standalone Part

It’s important to note: the 1335 Point Drill Claw is not sold individually at retail. It is engineered as part of an integrated drilling system, designed to match specific machine interfaces and operational parameters. This ensures optimal alignment, torque transfer, and safety. Bulk procurement is recommended for fleet uniformity and long-term supply stability, making it ideal for contractors, OEM partners, and large-scale infrastructure operators.

The Future of Industrial Tools: Smarter, Stronger, More Visible

As industries move toward digitalization and smart worksite monitoring, tools like the 1335 Point Drill Claw represent the next evolution — where physical performance meets digital readiness. In the future, color may integrate with AR-guided maintenance, IoT tracking, or predictive analytics dashboards. Today, it already serves as a bridge between human intuition and systemic efficiency.

The 1335 Point Drill Claw proves that in modern industry, function and form are no longer mutually exclusive. It delivers raw power, yes — but also clarity, identity, and control. Because in the end, the best tools don’t just work harder. They help you think smarter.